Colored or phosphorescent asphalts are an excellent solution for the construction of cycle paths, outdoor spaces in condominiums and play areas.

Colored Asphalt, a Durable Solution for Outdoor Flooring

One of the latest trends in thestreet furnitureof participatory urban planning and of the preparation of outdoor spaces concerns the use of colored flooring to report the different functions of space or transmit messages.

Example of decorated and colored outdoor flooring. Photo arch. Matteuzzi

The trend concerns both public spaces such as squares, sidewalks, cycle paths, sports facilities and children’s playgrounds; both courtyards and external appurtenances of condominium buildings or terraced house complexes.

However, such setups are usually made simply painting the pre-existing pavement (usually asphalt, concrete or interlocking paving) with the common exterior paint.

Colored external flooring with slight deterioration. Photo arch. Matteuzzi

Colored external flooring with slight deterioration. Photo arch. Matteuzzi

It’s a solution simpleeconomical and inclusivebecause it also allows the children of schools or to residents of the neighborhood to participate directly in the realization, but unfortunately very not very durable.

The paint comes off very quickly indeed damaged from atmospheric agents and from the wear and tear of the tramplingmaking the unrecognizable original drawing.

This should therefore be restored periodically, with a scheduled maintenance which in the long run turns out expensive in terms of costs, times and logistics.

Decorated outdoor floor degraded by the weather. Photo arch. Matteuzzi

Decorated outdoor floor degraded by the weather. Photo arch. Matteuzzi

An excellent one alternative it is therefore thecolored asphaltto cook advantages are decidedly numerous. In fact, in the face of a greater Initial investmentyou get a flooring with the same performancecharacteristics and resistance of the municipalities road surfacesresulting in a reduction in the maintenance required and related costs.

Uses and applications of colored asphalt

As already mentioned, the possible applications of colored asphalt are potentially unlimited.

One of the most common concerns, for example, the creation of pedestrian paths e cycle paths with a colored background, so as to make them immediately recognizable to motorists, and therefore decidedly safer.

Yellow asphalt cycle path, by CORECOM

Yellow asphalt cycle path, by CORECOM

The same principle also applies to pedestrian crossings: the most widespread solution involves the creation of a colored background (usually red) for the white stripes, or the provision of speed bumps of a visual type consisting of lines perpendicular to the direction of travel of cars.

Finally, we can classify the parking spacesassigning specific rights to some of them (reserved for example for residents, disabled people or electric cars) distinctive colors.

Sidewalk with red colored asphalt, by CISA Asfalti

Sidewalk with red colored asphalt, by CISA Asfalti

Setups of this type are very common, but normally made with the self-locking. However, the colored asphalt is more economic: a paving of interlocking blocks in fact requires the complete remake of the entire road package, while for the colored asphalt it is enough to replace the wear matthat is, the most layer superficial.

Other applications instead concern the creation of skating rinks, play areaslife paths and basketball courts or volleyball, or their embellishment with real ones works of art decidedly more durable than painted ones. These solutions are suitable for both public spaces of squares and urban parks, both at subdivisions of single-family homes, public housing complexes and supercondomini with large external appurtenant areas.

Cycle-pedestrian path with colored asphalt, by CORECOM

Cycle-pedestrian path with colored asphalt, by CORECOM

However, colored asphalt also lends itself well to much smaller projects, such as the redevelopment of anonymous courtyards con geometric decorations such as large chessboards, targets, zigzags, colored bands or mazes, which can also be used as a playing field.

Finally, colored asphalt can also play an important role in regulating the urban microclimate. A municipality black asphalt in fact it absorbs much more heat radiation compared to a light asphalt: a similar solution is currently being tested in Doha, where the streets have been painted blue.

Urban avenue with colored asphalt, by CISA Asfalti

Urban avenue with colored asphalt, by CISA Asfalti

This measure can be replicated, obviously on a smaller scale, in any courtyard, for example by marking the parking spaces with white, yellow or blue asphalt, joining three advantages: accumulate less heat during the day, redevelop external common areas and save on maintenance of horizontal road signs.

Types of colored asphalt outdoor pavements

From a technological point of view, there are more types of colored asphalt.

The first is thepoured asphaltobtained by mixing mineral aggregates with a hot bituminous mastic compliant with European regulations EN 12591.

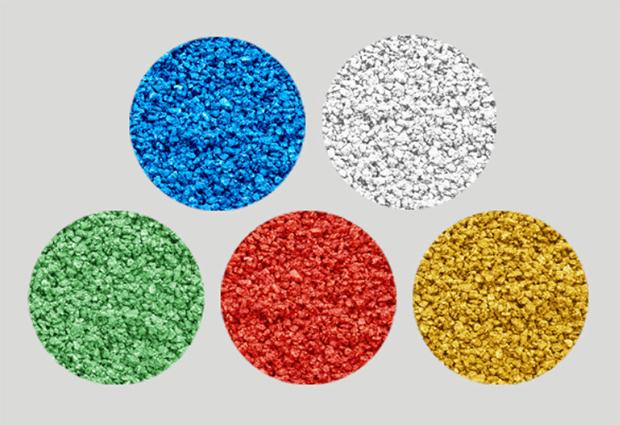

You can add to this mixture special pigmentsobtaining blue, red, green, yellow or beige asphalts.

Driveway with red poured asphalt, by CISA Asfalti

Driveway with red poured asphalt, by CISA Asfalti

The processingperformed by specialized companies such as CISA Asphaltsis very similar to that of common black asphalts and provides various stages.

For a new pavement, first of all the ground is prepared by removing the surface vegetation with its roots, the stones and the first layer of soil.

Subsequently, a drainage layer often 15-20 cm in quarry stabilizeda coarse gravel obtained by crushing the waste from stone processing: this subgrade is adequately pressed, levelled and compacted by means of aulli compressors.

Laying of poured asphalt, by CISA Asfalti

Laying of poured asphalt, by CISA Asfalti

Subsequently, the so-called attacking hand: consists of a thin layer of bituminous emulsion applied by spraying with a special machine, necessary to ensure better adhesion to the overlying layers.

The flooring also consists of three distinct layers.

From bottom to top the first is the undertone or all comers: often about 10 centimetres, it must withstand the vehicle stresses and be flexible enough to accommodate the land settlements.

Follows the binderan intermediate layer with a thickness of about 8 cm; while the most superficial layer is the wear matoften about 3 cm: when resurfacing a pavement with colored asphalt, it is often sufficient to replace only the latter.

Finally, immediately after the laying of the wear mat, while it is still hot, the entire surface is covered with a layer of grit with a grain size of 0.6-1.5 mm: for a better aesthetic effect you can use a pietrischetto of a lithotype already naturally colored.

Colored asphalts with transparent binder EVIzero by CORECOM

Colored asphalts with transparent binder EVIzero by CORECOM

Alternatively, the company CORECOM Srl he devised EVIzeroand transparent binder low environmental impact polyolefin for the production of wear mats.

Can be pigmented to obtain a colored flooring and is marketed in the form of chips solidi packed in PE bags.

Its preparation does not require special machinery, nor particular preparation by the workers, and it is applied manually or with a vibratory finisher.

Photoluminescent asphalt for night-time signaling

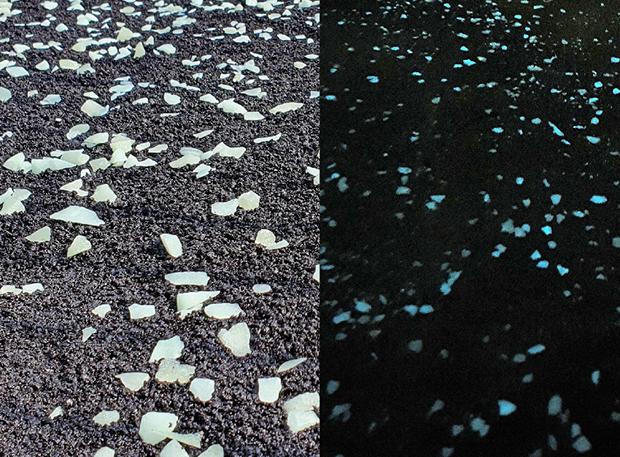

Colored asphalts have a disadvantage: they lose their signaling abilities when it is darkhowever, this inconvenience can be remedied with a photoluminescent flooringthat is, able to shine own light thanks to the phenomenon of phosphorescence.

Cycle path with phosphorescent asphalt, by Bright Materials

Cycle path with phosphorescent asphalt, by Bright Materials

Some minerals, including for example the white phosphorusin fact, they have the property of store artificial or natural light almost like a drumssubsequently returning it in the form of luminescence blue or greenish-white.

The term of this luminescence varies according to the amount of light stored and is between six and twelve hours: a photoluminescent flooring can therefore shine for aall night.

Photoluminescent grit for luminous asphalt, by Bright Materials

Photoluminescent grit for luminous asphalt, by Bright Materials

The number of refills possible, although potentially unlimited, depends strictly on the resistence to the wear and tear and weathering of the material used.

For this reason, the phosphorescent paints suffer from the same drawbacks (poor durability and need for periodic maintenance) as colored paints used for the low-cost renewal of urban spaces.

To obtain reliable, long-lasting and wear- and weather-resistant phosphorescent flooring, it is therefore necessary to choose innovative solutions.

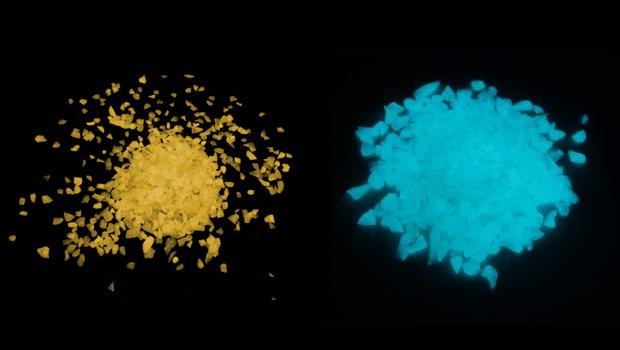

Phosphorescent grit for luminous outdoor floors, by Bright Materials

Phosphorescent grit for luminous outdoor floors, by Bright Materials

The company Bright Materials Srl for example, offers a special photoluminescent glass aggregate which can be used in both normal bituminous pavements (also pigmented), both together with transparent binders for greater brightness.

In this way, real projects can be created surfaces double facecolored during the day and photoluminescent at night.

Even in this case the possible applications concern both the road safetyboth the redevelopment of urban or condominium spaces with the creation of decorations and real works of art.

In fact, cycle paths can be created, sidewalkspaths and pedestrian crossings well marked even at night: although photoluminescence is too weak to completely replace thetraditional lightinghowever, it is a very promising solution especially on secondary roads and in the most isolated areas.

Source: www.lavorincasa.it