Have you ever wondered how your solar battery came to be? We visited the Bluetti factory, one of the players in the sector.

You are holding a Bluetti solar battery in your hands, compact and powerful at the same time. But have you ever wondered how this battery is made? I had the chance to visit the Bluetti factories near Shenzhen, China, and I’m going to take you behind the scenes of how these portable power stations are made.

From cell to pack

It all starts with the battery cells, the beating heart of your Bluetti. Contrary to what one might think, Bluetti does not manufacture its own cells.

The company uses a Chinese giant in the sector. But make no mistake, Bluetti’s work begins as soon as these precious cells are received.

Each cell undergoes a battery of tests (no pun intended) upon arrival. Voltage, internal resistance, temperature behavior… nothing is left to chance. The cells are then sorted with surgical precision. Why so many precautions? Because balance is the key to a high-performance and durable battery: “ We seek to create perfectly balanced ‘pairs’ of cells.« .

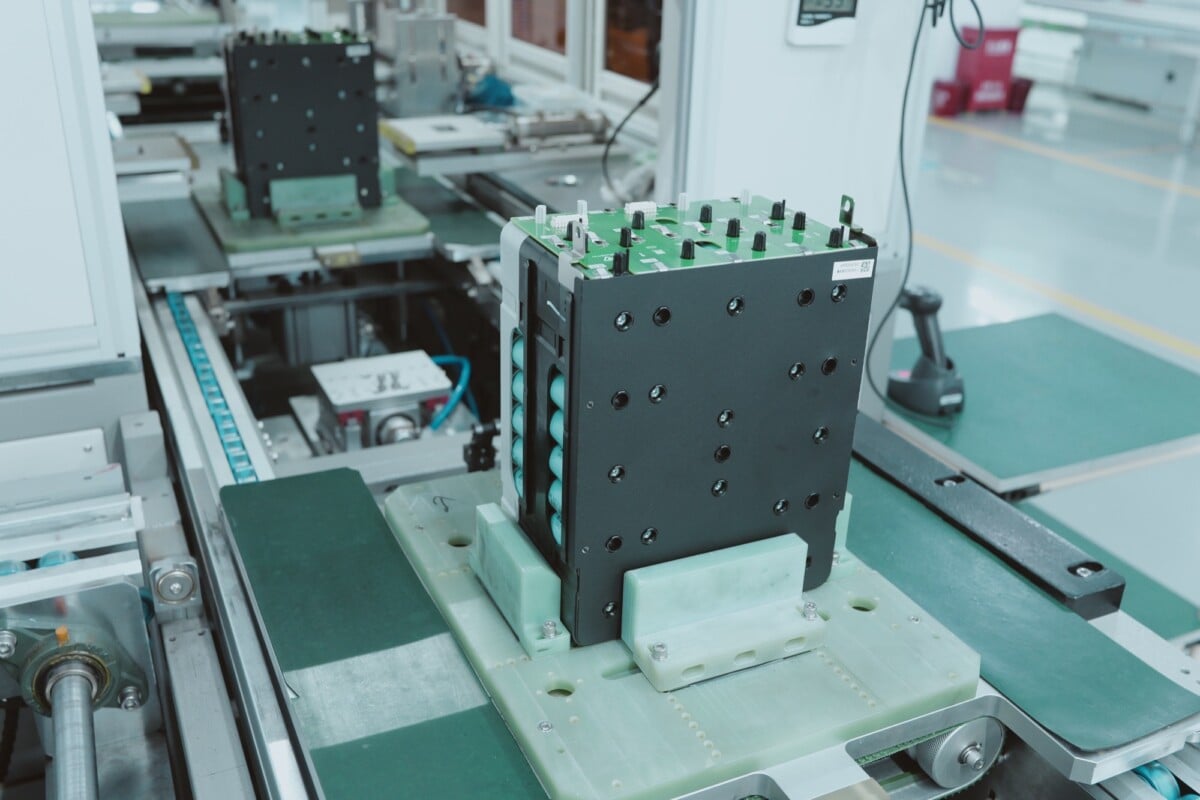

The process begins with cell selection. A sophisticated algorithm analyzes the characteristics of each cell — voltage, capacitance, internal resistance — and matches them optimally. Then, during charging and discharging, the battery management system (BMS) continuously monitors the status of each cell and adjusts energy flows accordingly. It’s like in an electric car, or a smartphone.

Once the cells are selected and paired, they are assembled into packs. This is where the magic happens: individual cells become a coherent whole, capable of storing and releasing energy efficiently. But this is only the beginning of the journey.

The brains of the operation

If the battery pack is the muscle of your Bluetti, the electronic card (motherboard, PCB, etc.) is its brain. And to build this brain, Bluetti does not skimp on resources.

« Our electronic assembly line uses the best in equipment“, a production manager proudly confides to me. “ We use the latest generation Yamaha editors. It’s like you’re doing haute couture, but for electronics. ».

The electronic assembly process is broken down into four crucial steps:

- Surface Mount Technology (SMT): This is where the smallest components are placed on the board with micrometer precision.

- Through-hole component insertion (DIP): for larger elements that require more robust fixing.

- Testing and programming: each card is tested and the firmware is installed.

- Conformal coating: a protective layer is applied to protect the electronics from external attacks.

« What is fascinating“, continues my guide, “ is that this part of production is almost entirely automated. Robots are much more precise and faster than us for these meticulous tasks. »

Here is a video filmed by Bluetti allowing you to see some of the tests carried out by the company.

L’assemblage final

Once the battery pack and electronic board are ready, it is time for final assembly. It is at this stage that we really see the solar battery that you will soon use take shape.

Unlike electronic assembly, this step requires more human expertise. “ Some tasks still require the know-how and flexibility of a human operator“, they explain to me.

We have approximately 60% automation in our factories, but final assembly remains largely manual. “. You should know that this rate can exceed 90% for a smartphone.

Bluetti

Each Bluetti passes through the expert hands of operators who meticulously check each connection, each screw, each joint. It’s a well-practiced ballet where every gesture counts.

Quality above all: tests, more tests

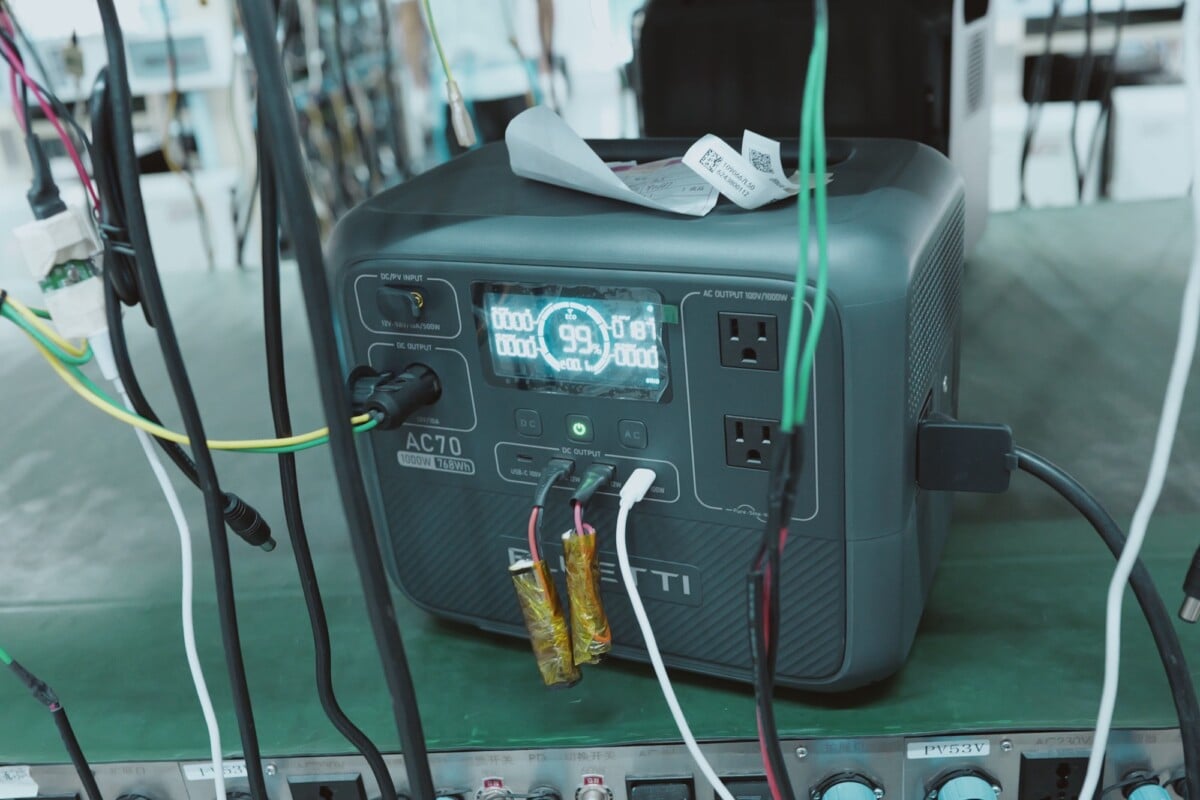

If you thought your Bluetti was ready to go after assembly… This is where a series of tests begins.

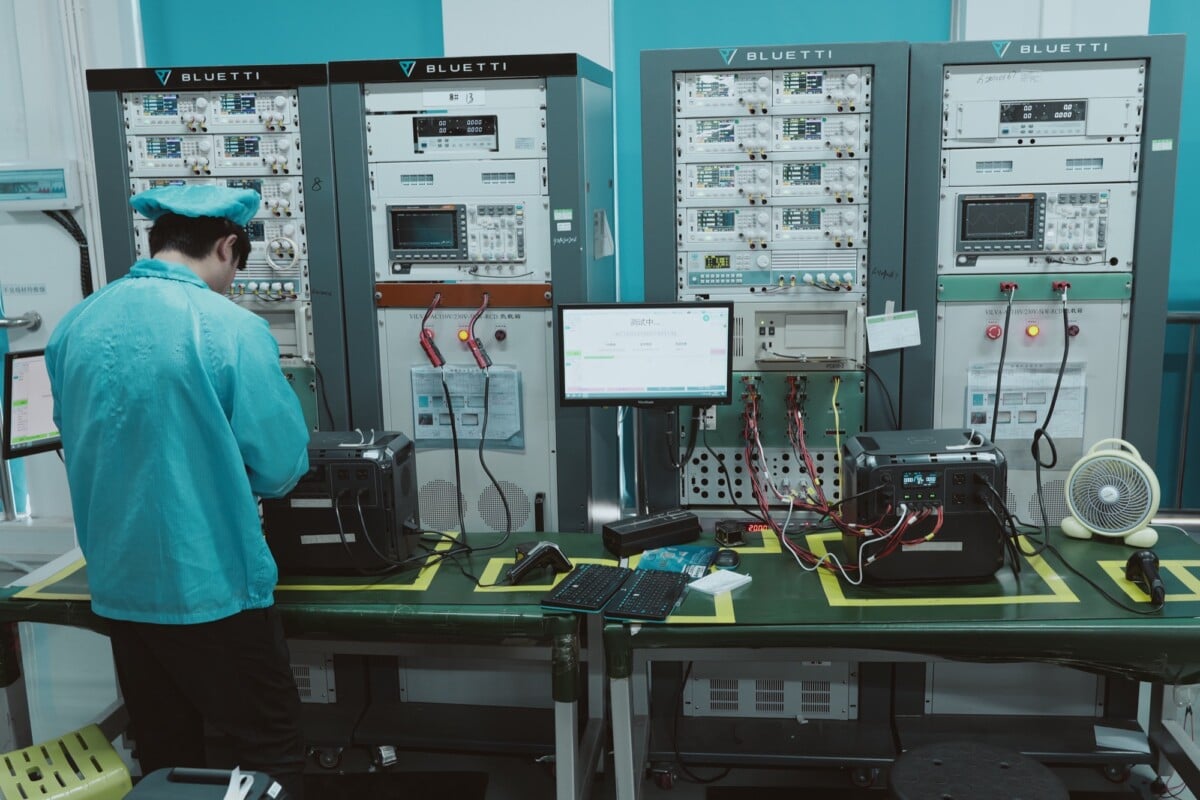

« We have 16 quality control processes in total,” the quality manager proudly tells me.z. Each stage of production is followed by verification. But the most impressive thing is what happens after assembly.

Each Bluetti battery undergoes an accelerated aging test. For several hours, it is subjected to intense conditions of use, simulating months of use in a few hours, ” we seek to identify potential defects before they appear to the customer“. Bluetti tells us that the energy is recovered to charge other batteries.

After this aging test comes the final test: the ATE, or Automated Test Equipment. This is a comprehensive test of the functionality and performance of each unit. Voltage, amperage, conversion efficiency… everything is scrutinized.

« Only after passing all these tests is a Bluetti battery considered ready for use“, concludes the quality manager. “ We prefer to be too cautious rather than risk disappointing a customer. »

What struck me most during this visit was Bluetti’s commitment to quality. The company doesn’t just assemble products: it designs, develops and tests them in-house. This is also what can differentiate the quality of two products, beyond the price. But you can’t check that in store.

To go further

What are the best “Plug and Play” solar panel kits? We tested them

Want to find the best Frandroid articles on Google News? You can follow Frandroid on Google News in one click.

Source: www.frandroid.com