Internal thermal insulation: critical issues and advantages of the internal coat. The construction criteria and the choice of materials in the construction of the thermal coat

Insulation of internal walls

The main system for isolate the internal walls are the internal thermal coat.

It is a thermally insulating layer which, when applied to the internal surface of the perimeter walls of the building (the dispersing ones, i.e. those in contact with the outside), reduces heat dispersion and cuts down on air conditioning costs.

We report in the photo an example of the healthy and breathable internal mineral insulation system with B-ISOLA panels. Bacchi Spa.

Internal insulation with B-Isola panels by Bacchi Spa

In a period in which energy costs are increasing dramatically, and there is an ever-increasing focus on energy saving, the practice of internal insulation of buildings becomes of great topicality.

The internal insulation system commonly defined as thermal coat, is installed by applying on the internal face of the perimeter walls interior insulation panels.

The panels used in this type of intervention are smaller than those used for the external coat. For this reason they take up less space.

Internal thermal coat with Steacomm cork panels

Internal thermal coat with Steacomm cork panels

In the photo above you can see the installation of a high-performance panel of the Steacom Srl made in corkso as to allow for minimum clutter.

Perhaps also due to their natural origin, as well as their aesthetic beauty, companies dealing with cork interior insulation panels. One is the Coverd Snc of which we report a creation made with SOKOVERD.Lv panels.

Internal thermal coat with cork panels SOKOVERD.Lv by Cover Snc

Internal thermal coat with cork panels SOKOVERD.Lv by Cover Snc

The execution of theinsulation of internal walls through the internal thermal coat technique is a very effective method.

This practice is recommended if you own an apartment in a condominium, where regulations may prevent any insulation work on external walls, and in cities, where it is difficult to carry out work that requires scaffolding or where there are architectural constraints.

The price of an internal thermal coat

Insulating internal walls by creating an internal thermal coat can be a expensive intervention.

However, adopting internal insulation will save you money in the long run.

Price per meter

The final cost of the internal thermal coat can vary based on the materials used and the difficulty of the intervention.

- Walls 18 – 25 €

- Roof 20 – 30 €

- Labor 17 – 22 €

- Scaffolding 10 – 13 €

- Final cost 47 – 65 €

How do you apply the inner coat?

Applying the internal thermal coat is quick and easy.

It consists only of 5 steps:

- preparation and cleaning of theplaster

- fixing of the vertical uprights in wood or aluminum

- pose of the insulating panels

- arrangement of one waterproof layer

- double drafting plasterboard layer and finish.

Assembly does not require particularly long times; for this reason the costs are reduced.

Choosing materials for the internal coat

Selecting the right materials for internal thermal insulation is a very important aspect. An internal coat requires a material highly breathable to avoid problems related to thehumidity; in fact, we often talk about internal anti-mold coat. However, each material has different prices and characteristics.

For this reason, being supported by an expert is essential to evaluate your case and choose the ideal typology for the home in question.

Mainly, there are two categories of materials to choose from:

– natural materialslike the super compact cork panel (pictured below) of the Steacom Srl;

Cork panel Steacom SRL

– artificial materialslike the Resphira Fassa Bortolo slab.Resphira Fassa Bortolo slab

Natural materials are generally more suitable for making a breathable internal thermal coat because they have greater insulating characteristics than artificial ones.

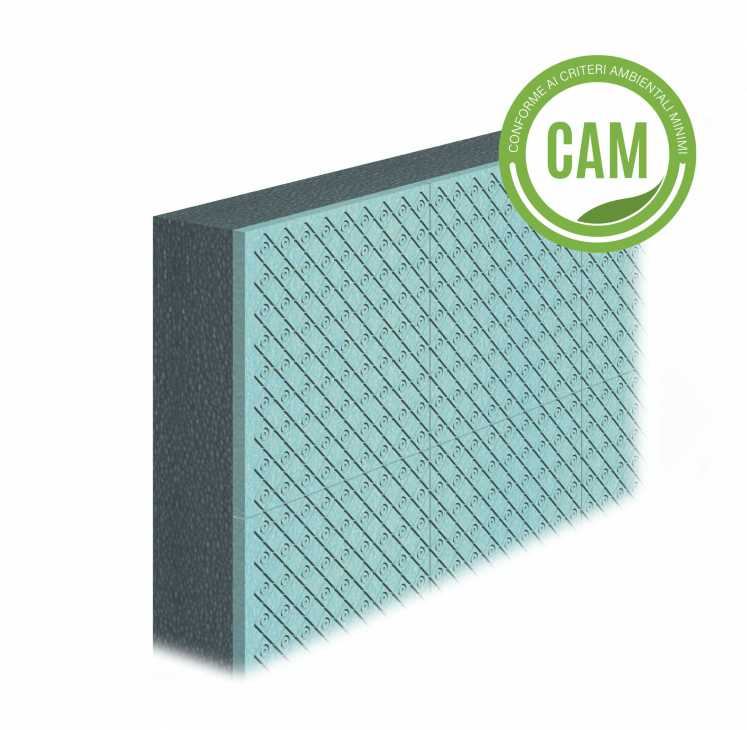

Artificial insulators are more cheap but a lot efficientincreasingly respectful of minimum environmental criteria, as in the case shown in the photograph of the EPS RESPHIRA insulating panel.

This patented micro-perforated EPS panel for thermal insulation is made by FASSA BORTOLO.

Despite the excellent technical characteristics, however, it is preferable that the panels are in climatic areas more trees or not very humid areas, precisely to avoid the onset of mold and humidity.

Internal coat, the criteria for its construction

Thermal insulation from the inside can be achieved with:

- pre-coupled insulating panels

- metal frame and sheets in plasterboard

- countermeasures

Pre-coupled insulating panels

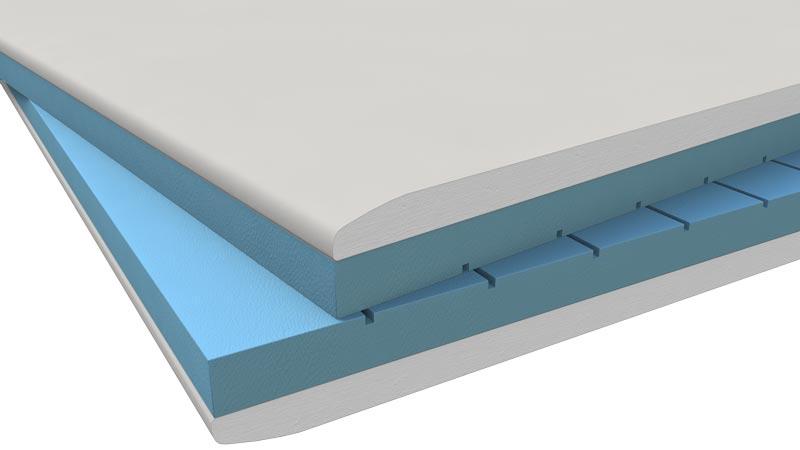

I pre-coupled insulating panels I am generally plasterboard sheets coated, coupled with an insulating panel and glued to the support.

The pre-coupled sheets can already have the vapour retarder or the vapor barrier.

XPS Knauf insulation system

Being glued to the support, the pre-coupled insulating panels have a high mechanical resistance. The final thickness is between 50 mm and 120 mm, depending on the insulating material used. The photo above shows an innovative system: theIsolastra XPS from the Knauf.

Plasterboard sheets and metal frame

In the frame system the application of the insulation is done on a frame with metal guides previously made and anchored to the support, here is an example of Bacchi spa.

This solution is recommended when there are false square walls or not perfectly plumb. For an effective solution, it is preferable to install a continuous vapor barrier directly on the frame.

Internal insulation in cavity with aluminum structures and plasterboard sheets Bacchi spa

Internal insulation in cavity with aluminum structures and plasterboard sheets Bacchi spa

The insulation material is installed between the uprights and the entire system.

Again, it is covered with plasterboard sheets fixed to the underlying frame.

The final thickness achieved is considerable: it can even reach 90 mm, in solutions with double-layer insulation.

Internal wall cladding

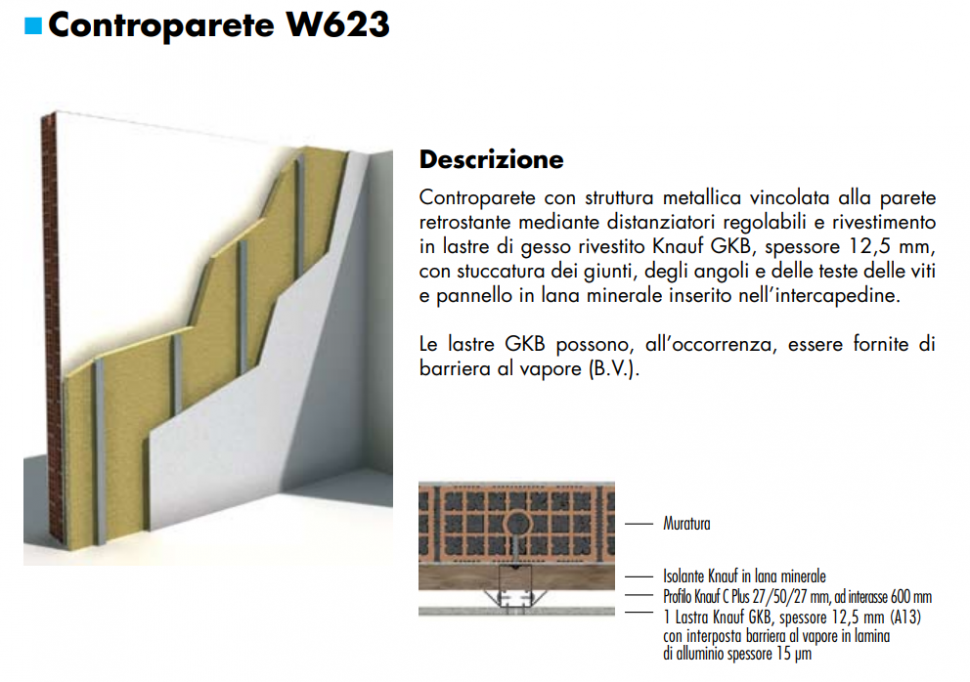

L’internal insulation against the wall consists of placing an insulating panel against a vertical wall and protecting it with a false wall.

The counter wall can be made of different materials, such as brick tilespanels in gesso o in cellular concrete.

The insulation, semi-rigid or in panels, is fixed mechanically or glued and, as previously mentioned, it is necessary to provide for the presence of a vapour barrier on the internal side.

Controparet W623 Knob

Considering the thickness of the insulating material and the counter wall, even in this case the final thickness is not negligible.

The thickness, therefore, subtracts precious square meters of net walkable surface, and this is certainly a weak point of this solution.

Another one criticality is due to the fact that the external wall is not protected and is therefore subject to temperature variations and the phenomenon of freeze-thawwhich could lead to the formation of the insidious thermal bridges.

This is why it is important to reiterate the need for a correct preliminary diagnosis.

The critical issues of the internal coat: what they are and how to solve them

When choosing this solution, it is also necessary to consider some critical issues that may arise.

The first concerns the thickness of the insulation itself, which reduces the usable internal space of the rooms.

For this reason, insulating materials are generally chosen that guarantee high performance with reduced thicknessescreating layers of only 5-6 centimetres.

In any case, we always proceed with a careful evaluation before carrying out the intervention.

The second criticality concerns the fact that the inner coat does not allow for the creation of a continuous layer of insulation, thus exposing oneself to the greater risk of the presence of any thermal bridges.

Even in this case it is possible to solve the problem thanks to the use of specific insulating materials useful for turning the insulation also on the attics, both roofing and floor.

Thus, problems due to lack of continuity are reduced.

Finally, the stratigraphy and the installation must be very precise to avoid the possible formation of condensaconsidering that the insulation is placed inside and the wall temperature drops further.

Therefore, when choosing the material it is a good idea to pay attention to both the performance in terms of thermal insulation that to the breathability.

Choosing the right material is essential to avoid condensation.

The advantages of the inner coat

This procedure is not very expensive but it allows for some savings in the long term. In fact, it allows for rapid heating of rooms with energy savings that are immediately visible. This makes the inner coat the ideal insulation system for private homes, where radiators are not active throughout the day and it is important to heat the rooms quickly.

Furthermore, thanks to the insulating panels, there is a notable reduction in energy resources necessary to heat or cool the home.

To recap, here is a list of the benefits that thermal insulation will bring to your home:

- greater living comfort;

- constant temperatures;

- energy saving.

The disadvantages of the internal coat

L’negative aspect It is made up of the loss of volume inside the house.

However, there is talk of a few centimeters.

Furthermore, application may be difficult in some areas of the house, for example behind large pieces of furniture, in the kitchen or behind radiators. It is therefore advisable to also plan for the disassembly and the reassembly of the furnishings and any radiators.

End of Article

The company specializes in solutions for green building, anti-mold remedies, acoustic and thermal insulation systems, finishes interior, home utilities, instruments for the execution of the works, waterproofing and humidity solutions.

It also manages technologies for safety at work in the industrial, artisanal and general work sectors; it markets an infinite number of products including wood and vegetable fibre insulation, cork, clay products, sheaths, sealants and accessories, products anti-moldsound-absorbing panels, silencers for ventilation holes, gaskets, brushes, power tools, hand tools, sheaths bituminous, breathable sheets, much more for the casa.

Source: www.lavorincasa.it

Cork panel Steacom SRL

Cork panel Steacom SRL Resphira Fassa Bortolo slab

Resphira Fassa Bortolo slab XPS Knauf insulation system

XPS Knauf insulation system Controparet W623 Knob

Controparet W623 Knob