Recent roller shutter boxes improve the performance of windows, contribute to energy saving and enhance aesthetics.

Roller shutter boxes, types and materials

I contemporary roller shutter boxes they are useful for containing roller shutters inside, inserted directly in correspondence with the wall partition, flush with it, without protruding, so as to be substantially invisible even if equipped with inspection opening.

There are currently several on the market tipi of bins: from the most classic ones to the technologicalfrom those insulated in aluminium which still manage to guarantee good thermal and acoustic insulation and are painted the same colour as the frame, to the external boxes, introduced subsequently on the external facade of the window compartment and equipped with a roller shutter, movement mechanism, sliding guides, fixing brackets, cap and winding roller, and again, those disappearing with high energy performance.

Renovating a house allows you to give a new aesthetic look to the environment but above all to improve its structure, the energy performancesafety, healthiness, comfort, and the bins traditional for roller shutters they are elements that need to be replaced because they are bulky, not nice to look at, generators of shadow areas due to their overhanging thickness, structures that are not acoustically and thermally insulated.

The roller shutter box is a structure in direct contact with the outside and therefore represents a thermal bridge important to design and implement with criteria and according to the building regulationsso as to avoid heat dispersion and reduce the use of heating or cooling systems during the summer season.

Advantages of roller shutter boxes

The new roller shutter boxes reduce the dispersions of heat and improve the healthiness and well-being of the environment, eliminating thermal bridges, humiditydrafts and noises coming from the window hole.

Today all this is possible by adopting technological bins MYBOX Of Climapac.

This box is first of all nice to look at even though it is a little protruding, it has high insulating performanceit is easy to assemble, useful if you want to replace the old structure without making other modifications or changing the window frame, equipped with a click hookmade in the square and rounded version.

It has a high air tightness and eliminates draughts and condensation, counteracting the formation of mould, it has a soundproofing power certified at 51 dB and can be supplied with the exclusive Silent Pack for greater performance. Furthermore, it improves energy efficiency and therefore helps to reduce heating and cooling costs and, consequently, to improve the Energy classification of the house by increasing its real estate value.

There is a design modern and can be painted the same color as the walls, it is easy to layeven in the case of large holes, and to be opened to carry out maintenance work; it is made to measure to adapt exactly to the window hole on which it is to be installed, it is supplied directly in a kit ready to be assembled with all the necessary accessories, it is made with reliable materials and with an industrialized production methodology tested for several years by the team ALPAC.

MYBOX Climapac is also available with the mechanical ventilation integrated control without any holes in the external wall for the intake and expulsion of air, all thanks to a patented system Climapac.

It’s a dumpster for redevelopments made to measure with an elegant and modern design, ready to paint, extremely silent with maximum efficiency sistema VMC which recovers heat and generates adjustable air flows, equipped with a heat exchanger double cross-flow counter-current enthalpic.

Retractable roller shutter boxes

The recent ones retractable bins They differ from traditional ones above all in that they are flush with the wall, invisible except for a thin thickness corresponding to the inspection opening useful for maintenance work. maintenance.

An example are the dumpsters EDILCASSdesigned to meet different requests and adapt to every window framewith excellent performance in terms of insulation thermo-acoustic thanks to the high density of the polystyrene and the galvanized iron reinforcement, eco-friendly due to the absence of chlorofluorocarbons.

EDILCASS retractable roller shutter boxes

They are produced in 6 linear metre bars, composed of expanded polystyrene self-extinguishing closed cell, electro-welded armour made of galvanized iron with a diameter of 4 mm and a pitch of 250 mm plus two lower aluminium profiles.

The whole is made solid with a stable, solid and light structure for the expansion of the polystyrene, the upper part is shaped with hollows dovetailed for better hookingarchitrave in concrete, the faces The sides are covered with cement mortar, wood fibres or bricks for the adhesion of theplaster and other finishes.

The elements that compose it are: dumpsterplaster net, quick-fit clamp, head panelbushing, cap, telescopic roller, celino guide, motorengine support.

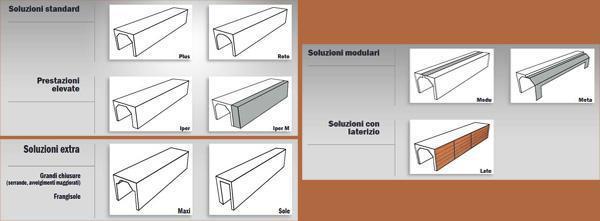

Different solutions for EDILCASS roller shutter boxes

Different solutions for EDILCASS roller shutter boxes

It is possible to ask for the standard solutions with a polygonal or rounded internal shape, the models from high performance equipped with a larger internal shoulder, the modular solutions with the appropriate variable filler profiles, with polystyrene inserts or with metal brackets, the brick systems.

This type of box can be inserted in many construction situations, in the presence of a pillar, in corner situations and therefore with a corner window, with a double frame or in the presence of a mullioned window; it is also produced in the round arch, low arch or double radius version, guaranteeing a notable economic saving in the processing of the window arch.

Maintenance through inspection of the container

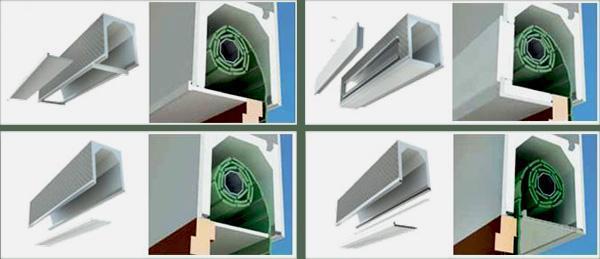

L’inspection Of roller shutter boxes It is useful for carrying out ordinary and extraordinary maintenance interventions, so it is necessary to choose the most appropriate method type of window frame that you own and the one you think is easiest to open.

Il sliding system It is adopted when the frame is in a bundle at the centre of the wall, it consists of a panel that slides on two lateral tracks, fixed in the lower part of the box, with the cielino sealed on a profile of the beat placed on the same window frame.

Different inspection systems for roller shutter boxes EDILCASS

Different inspection systems for roller shutter boxes EDILCASS

Il front type it is an inspection solution with an insulated front panel, while, that with a tampon has the lower ceiling in stop and is applied with both a flush and internally flush window frame; finally the inspection system with PVC ceiling it is interlocked in the aluminium support profile.

Monobloc roller shutter boxes for window opening

There are prefabricated roller shutter boxes, which with a simple clickjoin together shoulder pads e under the countercreating a monoblock solution for the window hole; thanks to the innovative brackets designed by engineers, they can be assembled quickly and easily on site, optimising the work of the installer, guaranteeing economic savings, offering high performance features.

The company INCOVAR is a company specialized in the design and construction of prefabricated containers for roller shutters completely built into the wall, Thermocass® It was the first experiment which was followed by new ones until reaching the Single System®monoblock with high-performance casing complete with side panels and under-sink.

Monobloc roller shutter box INCOVAR

Monobloc roller shutter box INCOVAR

The company offers ad hoc solutions to meet the needs of customers, responds to every request for the box system and provides products specific tailored; it is also divided into several compartments such as production, management, administration, purchasing office, technical division and other logistics and marketing sectors.

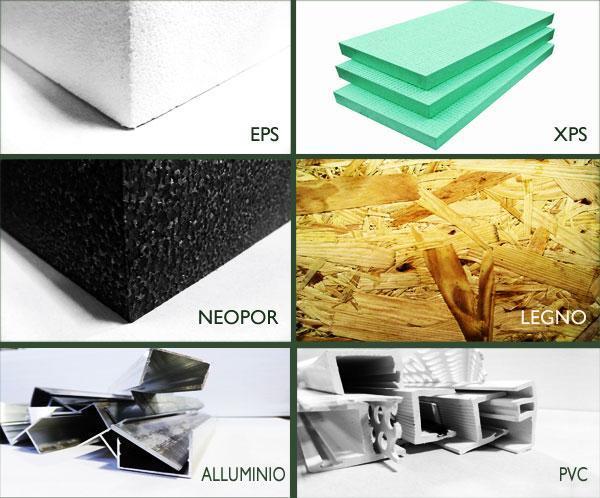

Materials used in INCOVAR roller shutter boxes

Materials used in INCOVAR roller shutter boxes

I materials mainly used by them to create the various models of box are based on theEPSsintered expanded polystyrene, or polystyrene consisting of a closed-cell structure containing only air, XPSexpanded polystyrene characterized by a closed cell structure effective as a thermal insulator and resistant to compression, NEOPOR BASFexpandable polystyrene obtained from the combination of EPS polymer and graphite, OSB WOOD/03technical wood-based panel composed of chips glued with a synthetic resin resistant to humidity and mechanical actions.

They also use thealuminum and the galvanized iron which are light and at the same time resistant, with a low thermal insulation value but irrelevant if placed in the correct way, and finally the PVC that is, polyvinyl chloride, a plastic material with high thermal insulating power.

Replacing traditional bins with a contemporary one is indeed a stylistic choice aimed at improving the aesthetics of the home environment but above all to improve the energy performance reducing heat loss, the formation of mould and damp stains.

Source: www.lavorincasa.it

EDILCASS retractable roller shutter boxes

EDILCASS retractable roller shutter boxes